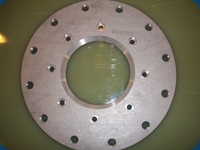

Waterjet and Tapped Flange for Water Park Application

Waterjet and Tapped Flange for Water Park Application

Waterjet and Tapped Flange for Water Park Application

Using a variety of manufacturing processes, including waterjet cutting, tapping, counter boring and beveling, Austin Waterjet was able to construct high-quality flanges intended for water park equipment applications. Offering a (+/-) .02 inch precision tolerance, we custom fabricated the waterjet and tapped flanges to match precise customer specifications.

Constructed from 304 stainless steel metal, the flanges measured .75 inches thick and sixteen inches in diameter. And, by offering a wide range of cost-effective manufacturing solutions, our company was able to build top-notch products for $300 less than competitors who use more traditional machining methods.

Specifications

- Capabilities Applied/Processes

-

Waterjet Cutting, Tapping, Counter Boring, Beveling

- Is it possible to machine this part?

-

Yes

- Savings with Waterjet Cutting vs. machining

-

$300.00

- Tightest Tolerance

-

+/- 0.02 inches

- Material Thickness

-

¾ inch

- Product Diameter

-

16 inches

- Product Width

-

3 inches

- Cutting Method

-

Waterjet Cutting

- Base Material

-

304 SS