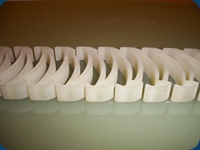

Waterjet Cutting of G-10 for Equipment Manufacturer

(click on thumbnail to enlarge)

Waterjet Finger for Production Equipment Manufacturer

Waterjet Finger for Production Equipment Manufacturer

Waterjet Finger for Production Equipment Manufacturer

Waterjet Finger for Production Equipment Manufacturer

Contracted by an equipment manufacturer to produce fingers, we were able to create superior products using our advanced waterjet cutting machinery. Providing a (+/-) .005 inch tolerance, we manufactured precision waterjet fingers of variable lengths that measured .5 inches in thickness. And, by using waterjet cutting technology to custom-build the customer’s products, we were able to meet exact client requirements while saving the manufacturer $1000 over more traditional machining processes.

Specifications

- Capabilities Applied/Processes

-

Waterjet Cutting

- Is it possible to machine this part?

-

Yes, but waterjet cutting is more cost effective

- Savings with Waterjet Cutting vs. machining

-

$1000.00

- Tightest Tolerance

-

+/- 0.005 inches

- Material Thickness

-

½ inch

- Product Length

-

variable

- Product Width

-

3 inches

- Cutting Method

-

Waterjet Cutting

- Base Material

-

G-10